Introduction

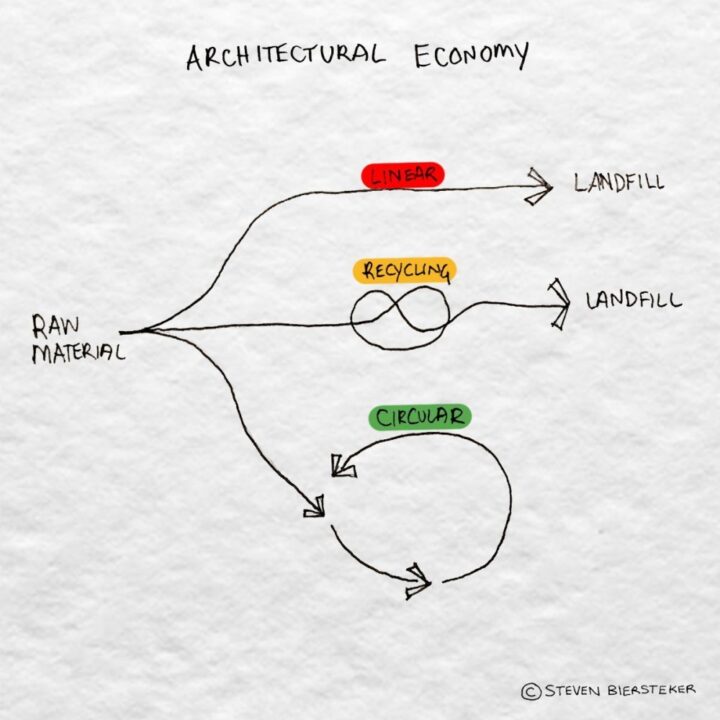

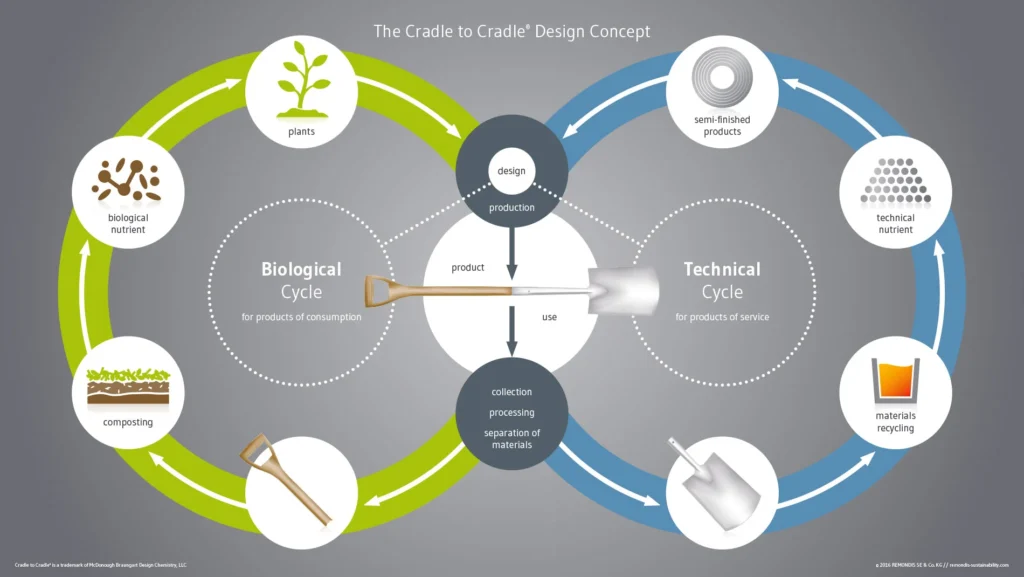

In an era where sustainable practices are paramount, the concept of the circular built environment has emerged as a beacon of hope for the future of the building and construction industry. Embracing circularity in this sector holds the potential to revolutionize the way we approach design, construction, operation, and end-of-life phases of buildings. By moving away from the traditional linear model of “take, make, dispose” to a more circular approach, we can minimize waste, conserve resources, and create a greener, more resilient built environment. Let’s embark on a journey through the stages of the circular built environment within the building and construction lifecycle.

01.

Design Phase

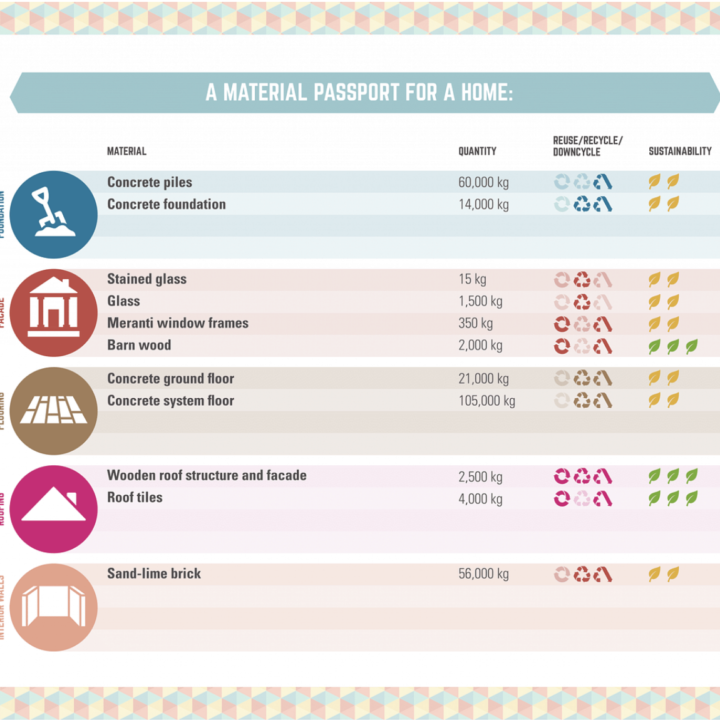

The circular journey begins with the design phase, a pivotal stage that sets the foundation for the entire building lifecycle. Here, designers play a crucial role in integrating circular principles into their blueprints. Key considerations include choosing materials with a lower environmental impact, designing for disassembly, and prioritizing modular and adaptable structures. Emphasizing energy efficiency and renewable energy integration is also vital, as it reduces the building’s long-term operational impact.

Collaborative efforts between architects, engineers, project managers, quantity surveyors and material experts help ensure that circular design principles are effectively incorporated while not compromising on functionality or aesthetics.